#Ultra compact nuclear fission reactor full

It can support both on-grid electricity and a range of off-grid clean energy solutions, enabling the decarbonisation of industrial processes and the production of clean fuels, such as sustainable aviation fuels (SAF) and green hydrogen, to support the energy transition in the wider heat and transportation sectors.īy 2050, a full UK programme of up to 16 of these power stations could create up to 40,000 jobs and £52 billion of value to the UK economy. Much of the venture’s investment is expected to be focused in the North of the UK, where there is significant existing nuclear expertiseĪ single Rolls-Royce SMR power station will occupy the footprint of two football pitches and power approximately one million homes.

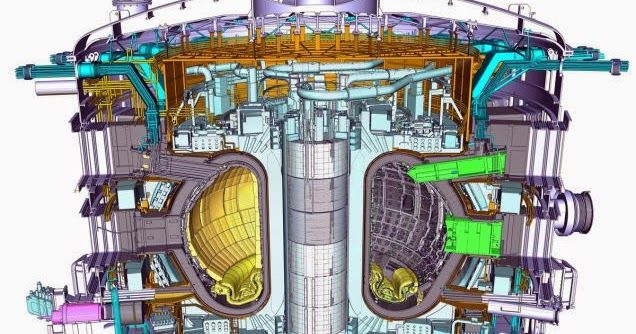

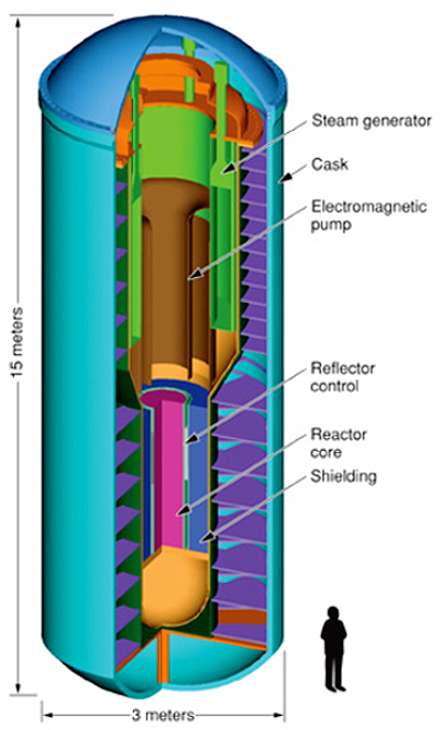

The Rolls-Royce SMR is a compact power station design, producing 470MWe from a Gen III+ pressurised water reactor (PWR).Īround 90 per cent of a Rolls-Royce SMR power plant will be built or assembled in factory conditions, and around 80 per cent could be delivered by a UK supply chain. Government will co-fund the selected technologies through their development, and work with successful bidders on financing and site arrangements. The process is managed by Great British Nuclear, and aims to select a number of technologies by autumn. In March 2023, the UK government announced a new competition to select the best SMR technologies for development in the UK. They are intended to complement the current generation of gigawatt-scale reactors, rather than be a substitute. With the UK’s net-zero commitments likely to require a quadrupling of low-carbon electricity generation by 2050, SMRs have a vital role to play in the energy mix. An initial SMR power station would be a fraction of the cost of a gigawatt-scale new build, could be built in four or five years and, once operational, will generate revenue to help finance additional units.īecause SMRs are designed to be largely made in factories, manufacturers will be able to use lessons learned from other sectors such as aerospace to drive down costs, and exploit new manufacturing techniques which aren’t approved for current reactor designs. SMRs should be much more affordable to build, by avoiding the huge upfront costs and decade-long development times of current reactors. The Rolls-Royce SMR is now targeting a delivery price of £40–60/MWh for its power station, a similar price to offshore wind generation. Initial cost modelling suggests that SMRs will not be significantly cheaper, in terms of capital cost per megawatt output, than the current generation of gigawatt-scale reactors once financing costs are taken into account. The term advanced modular reactor (AMR) usually refers to a variety of Generation IV reactor technologies which are at an earlier stage of development. SMRs are generally based on Gen III+ technologies which are relatively close to commercial readiness. The International Atomic Energy Agency defines SMRs as producing up to 300MW of electric power, but the term is applied to some larger designs – though all are smaller than the current generation of gigawatt-scale reactors.

Small modular reactors (SMRs) are advanced reactors that can be largely built in factories as modules to minimise costly on-site construction. If the UK can take an international lead in technology development, the UK supply chain could produce SMRs for the global market. Small modular reactors (SMRs) potentially offer significant opportunities to manufacturers.

0 kommentar(er)

0 kommentar(er)